"What are the certification standards for G6 micro switches?"

In the field of electronic components, as a critical control element, the safety and reliability of microswitches directly impact the performance of end devices. The G6 series of microswitches under ZINGEAR Group, with its stringent quality control system, has established a certification network covering major global markets, providing a solid guarantee for the product's international competitiveness.

I. Global Certification Standards System for Microswitches

Microswitch certification standards can be categorized into three main types based on application scenarios:

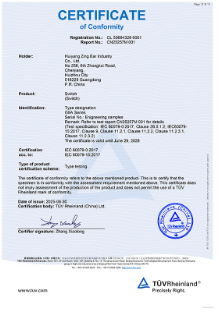

1.Basic Safety Certifications: UL (U.S.), cUL (Canada), and CSA (Canada) form the core for North American market access, while ENEC (EU) and TÜV (Germany) represent the highest safety standards in Europe. PSE (Japan) is a mandatory certification in the East Asian market.

2.Country-Specific Mandatory Certifications: These include China's CCC certification, South Korea's KC certification, Russia's EAC certification, etc., serving as regional market entry barriers.

3.Industry-Specific Certifications: These include special environmental certifications such as AEC-Q200 for automotive electronics and MIL-STD-810 for military-grade applications.

II. ZINGEAR Group's Certification Advantages

All products from Huizhou Weidong Technology Co., Ltd. (ZINGEAR Group) have obtained globally recognized certifications including UL, cUL, CSA, ENEC, TÜV, CE, PSE, CQC, and CCC, forming the following technical advantages:

1.Electrical Performance Certification: Compliant with UL 61058-1, ensuring 100,000 mechanical cycles and 50,000 electrical cycles.

2.Environmental Adaptability Certification: Meets the IEC 60068-2 series standards, covering 12 environmental tests including vibration, shock, and salt spray.

3.Material Safety Certification: All models comply with RoHS 2.0 and REACH regulations, with heavy metal content below 50% of the limit.

III. Capacity Upgrade with the Cambodia Factory

With the completion and operation of the Cambodia factory, ZINGEAR Group has formed a "3+1" global manufacturing layout.

IV. Market Value Brought by Certifications

1.Technological Barrier Breakthrough: TÜV certification enables the product to obtain the EU CE mark, with an export tax rebate of up to 12%.

2.Cost Optimization: CQC certification reduces procurement costs for domestic customers by approximately 15%.

3.Delivery Assurance: The Cambodia factory shortens the delivery cycle for Southeast Asian orders to just 7 days.

With the full operation of the Cambodia factory, ZINGEAR Group has the capability to provide global customers with a "certification + capacity + service" integrated solution, continuously consolidating its leading position in the microswitch field.