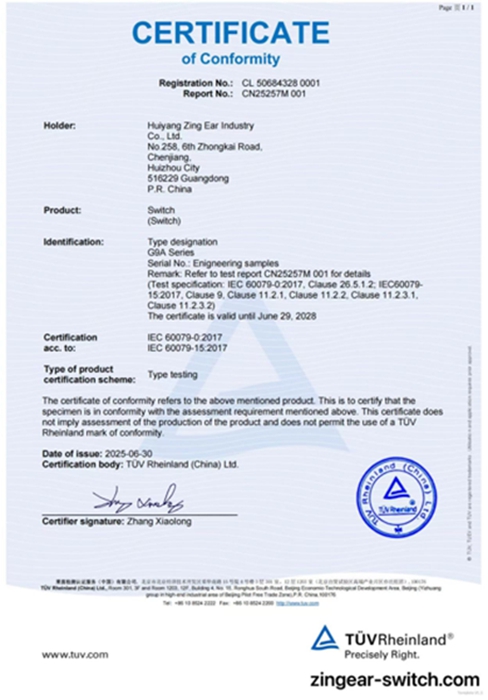

"ZINGEAR Group's core products have passed international explosion-proof certification"

1、 Strict certification implementation, balancing explosion-proof performance and home appliance adaptation requirements

This explosion-proof certification is fully audited by an international authoritative organization in accordance with the ATEX 2014/34/EU directive and the IEC 60079 series standards, covering multiple core indicators such as product structural safety, temperature control, and insulation protection. It has undergone rigorous processes such as explosion-proof structural integrity testing, short-circuit arc protection testing, high and low temperature cycling testing, and anti vibration impact testing.

Finally confirmed, ZINGEAR micro switch products can operate safely in hazardous environments such as flammable and explosive gases (such as methane, propane), dust suspension, etc. The temperature group reaches T4 (maximum surface temperature ≤ 135 ℃), and the protection level meets the IP67 standard, fully meeting the requirements for use in Class II, 3G hazardous areas. In response to the special application scenarios of household appliances, the technical team has achieved a dual breakthrough of "safety and adaptability" in explosion-proof design: adopting a miniaturized explosion-proof shell design to adapt to the compact installation space inside household appliances; Choose high temperature resistant engineering plastics with flame retardant grade UL94 V-0, balancing explosion-proof and lightweight requirements; The contacts are made of anti-oxidation silver alloy material and inert gas protection, which not only avoids the risk of arc ignition, but also meets the durability requirements for high-frequency start stop of household appliances (with a mechanical life of over 500000 times).

According to third-party laboratory testing, the failure rate of certified products in simulated kitchen oil and gas environments and dust cleaning scenarios is less than 0.001%, far exceeding the explosion-proof safety threshold of the home appliance industry. The demand for explosion-proof in the field of household appliances is rapidly increasing, especially in scenarios such as kitchen appliances and outdoor industrial grade appliances, which require extremely high safety redundancy for switches. The R&D leader of the group stated that this certified product has solved the safety hazards of traditional household appliance switches in oil and gas and dust environments by optimizing the circuit insulation structure and strengthening the sealing protection design, while maintaining the low-power and small volume adaptability characteristics of household appliances. It can be directly integrated into various explosion-proof household appliance control units.

2、 Certification empowers multiple scenarios, continuously expanding the application boundaries in the home appliance field

The approval of this explosion-proof certification has opened up a dual growth space for ZINGEAR products, combining traditional high-risk areas with emerging home appliance markets. Among them, the core application scenarios in the field of home appliances include:

-Explosion proof kitchen appliances: compatible with gas stove ignition control switches, embedded oven temperature control switches, integrated stove safety interlock switches, etc., to block the risk of arc ignition in kitchen oil and gas intensive environments and ensure cooking safety;

-Outdoor/industrial grade household appliances: provide explosion-proof control accessories for mobile air conditioners, outdoor refrigerators, and specialized household appliances for mining camps, to cope with complex outdoor environments and potential hazardous media;

-Special environment appliances: meet the safety control needs of supporting appliances in chemical industrial parks, dust workshop cleaning equipment (such as explosion-proof sweeping robots), high humidity industrial washing machines, and other scenarios, filling the gap in industry adaptation;

-High end export home appliances: The product compliance fully complies with the explosion-proof standards of home appliances in the European Union, North America and other regions, helping home appliance customers break through international market access barriers and expand into high-end segments.

At the same time, the competitiveness of certified products in traditional high-risk fields such as petrochemicals, mining ventilation systems, and hazardous chemical storage equipment has been further strengthened, forming a market pattern of "home appliances+industry" dual coverage. Relying on a mature global supply chain system, the overseas delivery cycle of certified products can be controlled within 7-15 days, providing a dual guarantee of "compliance+efficiency" for home appliance enterprises and industrial customers. Currently, we have received cooperation consultations from multiple high-end home appliance brands.

3、 Deeply cultivate the construction of compliance system and consolidate the competitive advantage in the field of home appliances

As a core enterprise deeply involved in high-end manufacturing and new energy accessories, ZINGEAR Group has always regarded product compliance as the core prerequisite for market expansion. Previously, the group's products have passed ISO 9001, IATF 16949 quality system certification, as well as multiple international safety certifications such as UL, CE, CQC, etc. The implementation of explosion-proof certification further improves the comprehensive certification matrix of "general scenario+special scenario", especially for the safety needs of the home appliance field, forming a differentiated competitive advantage.

Home appliance safety is directly related to the end-user experience, and explosion-proof certification is the 'key to entry' for high-end home appliances into professional scenarios. ZINGEAR will take this certification as an opportunity to continue to increase investment in the research and development of home appliance explosion-proof technology: targeting specific scenarios such as kitchen appliances and outdoor appliances, we will launch a customized micro switchseries to optimize key parameters such as product size, operating power, and lifespan; Collaborate with home appliance companies to carry out collaborative research and development, create an integrated control solution of "explosion-proof+intelligent", and adapt to the trend of home appliance intelligence and networking; At the same time, deepen cooperation with international certification agencies, proactively layout more compliance certifications related to home appliances, and help customers seize the opportunity in the high-end home appliance market.

At present, ZINGEAR Group's explosion-proof certification products have officially opened global order docking, especially providing customized adaptation services for home appliance enterprises. Customers can consult and purchase through the group's official channels. With the continuous improvement of compliance system and the continuous expansion of home appliance application scenarios, ZINGEAR will further highlight its differentiated advantages in the high-end manufacturing track, empower home appliance safety upgrades with technological compliance, and achieve mutual benefit and win-win with global partners.