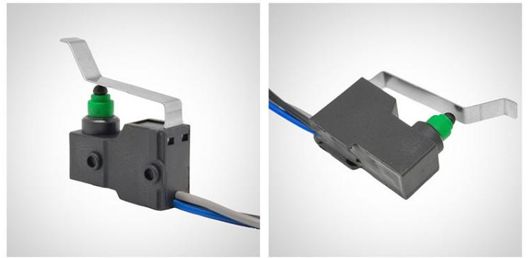

"Zingear G305 series micro switch: safeguarding brake safety, serving as a "reliable defense line" for instantaneous response"

In automotive active safety systems, the reliability of the braking system is directly linked to the safety of occupants. As the core component for monitoring brake status, the micro switch must complete signal transmission within milliseconds to ensure that electronic assistance systems (such as ABS, ESP) perceive braking actions in real time. The G305 series micro switch from Zingear, with its high-precision triggering, automotive-grade durability, and extreme environmental adaptability, has become the preferred solution for brake system signal sensing. This article will delve into how the G305 supports "big safety" with its "small components."

I. Micro Switches in Brake Systems: The "Key Sensing Node" in the Safety Chain

The demand for micro switches in brake systems is concentrated in three core scenarios:

Brake Pedal Position Detection: Provides real-time feedback on pedal travel to assist the ESP/ABS system in regulating brake force distribution.

Handbrake/E-Parking Brake Monitoring: Confirms the parking state to prevent accidental vehicle rollaway.

Brake Pad Wear Warning: Triggers a signal through displacement to prompt replacement of excessively worn brake pads.

The Zingear G305 series is specifically designed for high-load, high-vibration environments. Its core value lies in:

Instantaneous Response: Triggers a signal with just 0.1mm of displacement, with a response time of <5ms, ensuring the electronic system simultaneously perceives braking actions.

Zero False Trigger Design: The snap-action mechanism triggers at the critical point, eliminating signal jitter caused by mechanical vibration.

Extreme Environmental Tolerance: Adapts to complex working conditions such as high/low temperatures, humidity, dust, and vibration while maintaining stable performance.

II. Technical Highlights of the G305 Series: "Safety Genes" Tailored for Brake Systems

1. Over-Spec Electrical Performance

Rated Load: 5A/250VAC, compatible with 12V/24V vehicle systems, meeting the demand for high-current signal transmission.

Low Contact Resistance: Silver alloy contacts with gold plating, with a resistance value of <20mΩ, reducing signal loss.

Anti-Arcing Design: Optimized contact spacing suppresses arc generation, extending service life.

2. Automotive-Grade Mechanical Structure

Mechanical Life: ≥500,000 operations, covering the vehicle's entire lifecycle.

Protection Rating: IP67 sealing design, dustproof and waterproof, resisting brake fluid leaks and high-pressure car wash sprays.

Vibration Resistance: Passes high-frequency vibration tests (10-55Hz), suitable for harsh scenarios in commercial and engineering vehicles.

3. Smart Function Expansion

Dual Contact Redundancy: Simultaneous switching of Normally Open (NO) and Normally Closed (NC) contacts allows the BCM to cross-verify signals, avoiding false alarms.

Temperature Compensation Mechanism: Built-in special material reeds maintain elasticity even in -40°C cold, preventing contact adhesion.

III. Typical Applications of the G305 in Brake Systems

1. Electric Parking Brake (EPB)

Installed in the handbrake cable or motor actuator to monitor the parking status in real time.

The triggering signal links with the electric parking module to ensure the wheels are locked when the vehicle is stationary.

2. Brake Pedal Travel Sensor

Serves as a calibration element for the pedal position analog signal, assisting the ESP system in precisely adjusting braking force.

During emergency braking, it quickly transmits the "full braking" signal to activate the ABS anti-lock function.

3. Brake Pad Wear Monitoring

Integrated into the brake caliper or guide rail, it triggers an alarm signal through displacement changes.

Alerts the driver to replace the brake pads in time to avoid a decline in braking performance.

IV. Why Choose the Zingear G305? Three Core Advantages

1. Full Coverage of Automotive Certifications

Certified with AEC-Q200, compliant with ISO/TS 16949 quality standards, meeting the supply chain access requirements of global automakers.

Adaptable to various vehicle types, including passenger cars, commercial vehicles, and new energy vehicles.

2. Customized Solutions

Offers customization options such as pin direction, operating force (2N-10N), and housing material (flame-retardant PC/nylon).

Supports small-batch rapid prototyping to shorten customers' product development cycles.

3. Full Lifecycle Support

Provides one-on-one service from the technical team, from selection guidance to mass production delivery.

Offers cost-optimized solutions to help customers balance performance and budget.

V. Selection Guide: Key Parameters for Micro Switches in Brake Systems

Electrical Requirements: Choose the rated load based on the system voltage/current, leaving a 20% margin.

Installation Fit: Measure the installation space and choose between ultra-miniature (G305-S) or standard-sized models.

Environmental Adaptability: Select high-temperature-resistant models (operating range -40°C to +125°C) for high-temperature regions, and IP67 protection for humid environments.

Signal Redundancy: Prioritize dual-contact (NO+NC) models for safety-critical scenarios.

Conclusion: The Zingear G305, the "Last Line of Defense" for Brake Systems

In the safety-sensitive field of brake systems, the Zingear G305 series micro switch has become the "invisible guardian" ensuring braking safety, with its instantaneous response, automotive-grade reliability, and flexible adaptability. For automakers and Tier 1 suppliers, choosing the G305 is not only about meeting functional requirements but also about upholding a commitment to safety.

Tags: High precision micro switch brake system micro switch signal sensing micro switch

Related Recommendations

-

Can my brand logo be printed on the micro switch? ZINGEAR micro switch supports customization

2026-02-12 -

The differences between Micro Switch and Limit Switch

2026-02-12 -

Which brand of mouse micro switches is the best? Deep analysis and recommendation

2026-02-12 -

The Robust G9 Waterproof Micro Switch: Design, Applications and Manufacturing Excellence by ZING EAR

2026-01-13 -

G201 Sealed Micro Switch | ZING EAR China ODM & OEM Manufacturer

2026-01-13